The National Automotive Design and Development Council (NADDC) announced it has established the necessary structures and frameworks to begin local production of vehicle spare parts.

This initiative is aimed at reducing Nigeria’s reliance on imports, which currently cost the country $1 billion annually.

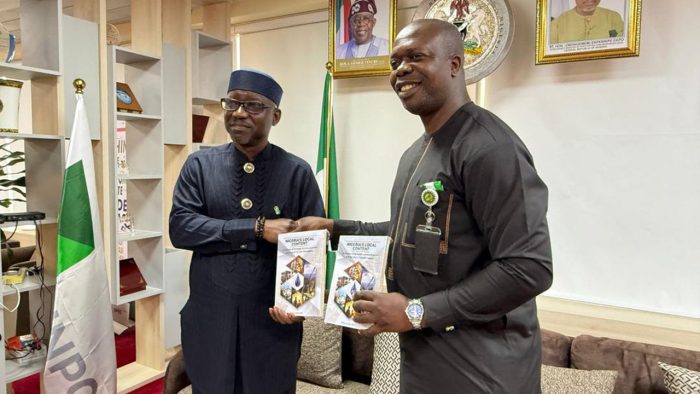

The NADDC Director General, Joseph Osanipin, disclosed this during the conclusion of a two-week automotive engineering and software design training held in Abuja organised in partnership with Midas IT Co. of South Korea, focusing on Midas NFX software, a platform for advanced design and analysis.

Speaking on behalf of the DG, the Director of Research Design and Development, Fidelis Achiv, highlighted the council is committed to transforming Nigeria’s automotive industry by increasing the percentage of locally manufactured components in vehicle assembly.

“We are working to achieve a level whereby we can go back to assembling vehicles that have up to 40% locally manufactured components. We have vehicle assemblies in Nigeria but the assembling that is going on is not adding much value to the economy.

“Vehicles that have been assembled come in completely built, and they just remove the tyres, remove the exhaust system, remove the engine, ship them, and come and assemble them here. But we want to transform from that to a level where these vehicles come in unpainted, the welding is done here, some components parts are produced here and the assembly will add more value, and employ more people. We have over 11 million vehicles on our Nigerian roads.

“Of the over 3,000 parts in a vehicle, if we can leverage on producing just 10 that we can beat our chest, that in the whole world, Nigeria produces these 10 components and they are best, the market is going to be huge. Our economy will change,” he stated.

The training boot camp, which hosted 15 participants, aims to equip engineers with the skills necessary to achieve this vision.

“The essence is to train engineers to design and produce parts, making Nigeria self-sufficient in vehicle parts production,” Achiv explained.

Fostering innovation

- Abdul-Lawal Zubair, Managing Director of FAZSAL Nigeria Limited, encouraged participants to apply their newly acquired skills practically and creatively to address challenges in the automotive industry

“You have not just seen the theory of design but with practicality. Solve the issues for us. There is a reason among all the software for this agency to choose Midas NFX.

“Let them be proud of you. They can call you for advanced training, possibly in South Korea. Don’t just know the software and keep it. Be innovative and give solutions,” he said

- One of the participants, Lukman, expressed gratitude for the opportunity and the exposure to the advanced Midas NFX software.

“This training has widened my level of thinking and reasoning. The software is outstanding for modelling and analysis. We are now more equipped to be creative and contribute to producing what we consume. This software offers a platform for optimizing design and introducing innovative ideas into the market,” he stated.

SOURCE: NAIRAMETRICS